Deinking and decoating of plastic food packaging for recycling

by Marianne Wink

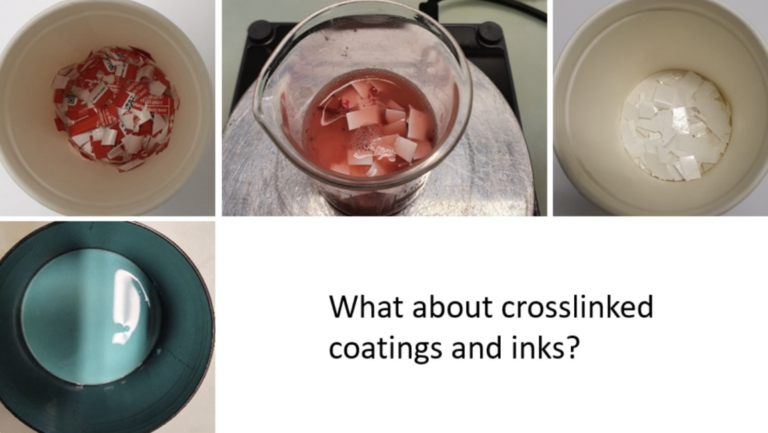

To make plastic packaging more sustainable, its recycling has to increase dramatically. Today, the vast majority of recycled plastics are PET bottles. Other very common plastics for food packaging, especially polyolefins, could technically be recycled but are only done so in small volumes. One of the reason for this is that the recycled materials do often not match the quality of virgin ones. Coatings or printing inks on the packaging lead to contamination of the recycled material. Although efforts in designing packaging for recycling can reduce the amount of this contaminating substances, some are inevitable. Adding an additional step to deink or decoat plastics from packaging before recycling helps to increase the quality of the recycled plastic and thus turns it into a more circular product. Although a few standard methods for plastic deinking exist, they only work for selected types of ink or coating chemistries. Especially, any crosslinked inks or coatings, as for example liquid toner inks or UV inks and coatings, are very hard to remove. To address such coatings or inks, newly adapted deinking techniques are necessary. We want to develop such new techniques to remove crosslinked inks or coatings from plastic packaging. One idea is to explore different types of mechanical actions in combination with already existing protocols. Alternatively, finding ways to break down coatings and inks chemically before removal are an attractive option. First trials to do so are currently underway. The main challenge will likely be to upscale the proposed processes. Especially the latter would require the build-up of completely new plants. Further, it is important to ensure that no small molecules, which could migrate out of the recycled plastic, are created in the process and left in the recycled material.

Solid

Cooled – Fresh products & short shelf life

The types of plastics that are interesting for our process are those materials that are per se recyclable. Packaging made from a single material polyolefin is ideal. Further, the developed process could not only be used for post consumer waste but also for post industrial waste.

Being able to remove a wide range potential contaminants before recycling and thus achieving a higher quality of the recycled plastic is one of the key steps in order to ramp up recycling of food packaging. Apart from PET recycling, plastic recycling in Switzerland is bound to grow tremendously in the coming years. With this idea, we aim to add an extra step that potentially gives the recyclers a competitive advantage in terms of recycled materials quality. Also, it might allow to recycle materials that are so far not deemed recyclable yet.

- How can we remove “hard-to-remove” inks and coatings from plastics mechanically and/or chemically?

- How can we make sure these deinking procedures leave no residue and do not create migratable species?

Recycler’s perspective and input, packaging producers providing us with samples, pilot plant once the process is established.

As it holds to potential to boost plastic recycling, this idea clearly has a significant environmental impact. In the best case, we manage to keep materials in the loop that are so far not recyclable yet. In the long run, recycled materials will also be attractive economically due to limited resources. Building up the expertise in plastic recycling in terms of deinking and decoating can create jobs in Switzerland and thus is also sustainable on a social level.