Water and Nutrient Circularity as a Service (WaNCaaS) - New business models for closing the water and nutrient cycles in the food industry

by Maximilian Grau

Our project tackles the challenge of closing the water and nutrient loops around food industries, to promote the sustainable use of water and to enable nutrient recovery. “There is potential to increase the volume of circulating nutrient and matter, decrease the intake of new nutrients and matter and close the loops partially”, including at the food production stage (p.2, Jurgilevich et al., 2016). The food industry is well aware that side streams should now be considered and handled as main streams (GDI, 2023; Ellen MacArthur Foundation, 2021) . Yet much is being done to valorize the solid wastes or “by-products” (personal communications from two Swiss food industries during the interviews carried out in the incubation phase), while valorizing the liquid streams seems so far less of a priority in the food industry.

Wastewater from the food industry comes from the process units, rinsing and cleaning activities and the formation of by-products (Shrivastava et al., 2022). Some solid-rich or nutrient-rich wastewater from the food industry is commonly reused as animal feed. For instance, whey (sometimes concentrated by reverse osmosis and steam-pasteurised) produces lactose and protein-rich feed such as whey powder, whey protein concentrate, fat-filled whey or whey permeate (FEFAC, 2022). Wastewater from vegetable preparation is filtered to remove the solid parts and decanted to remove the fats. The remaining pulp complements animal feed. The remaining wastewater is treated, and the treated wastewater is released in the local surface water. Alternatively, the wastewater is neutralized and transported to the local wastewater treatment plant through the sewage network. The following uses of the liquid waste streams from the food industry are underexplored in Switzerland so far:

- reuse to irrigate nearby fields,

- productive nutrient recovery (e.g. micro-algae production, bioponics, etc.),

- reuse as process water in the factory to close the water and nutrient cycle.

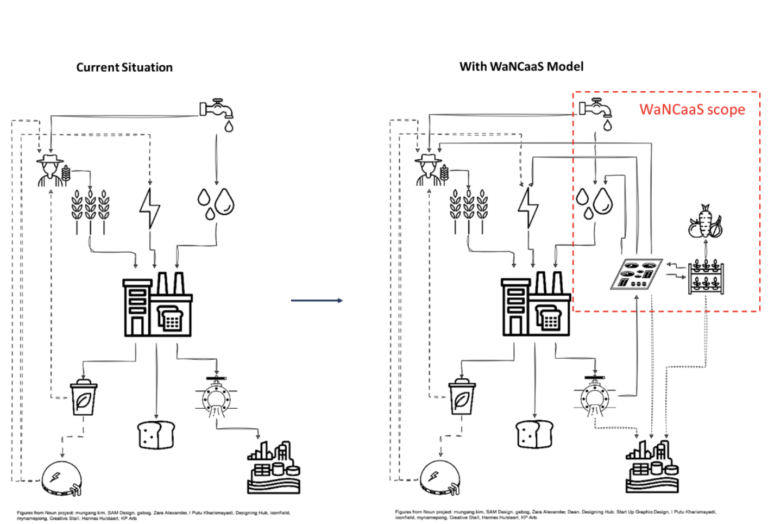

However, most food industries are mainly concerned with processing and producing food, and not with the provision, treatment and re-use of water and wastewater, or the potential of nutrient recovery in the liquid waste streams. Thus, we propose to position our solution as an “as-a-service” model . An external service provider manages the water and nutrient circularity as an external service to the respective industry. A contractual agreement between the industry and service provider regulates the responsibilities and pricing of, for instance, clean water and nutrients recovered from side streams. Such developments are already taking place: some companies currently offer water-as-a-service to industrial clients (e.g., www.waterleau.com, www.veoliawatertechnologies.com/en/water-service). We propose to extend such a service to include nutrient recovery: we propose “Water and nutrient circularity as a Service (WaNCaaS)”.

Additionally, we include the concepts of water stewardship (CEO Water Mandate from UN Global Compact) to reach a holistic service model considering the regional specificities of the food industry. Taking into account the regional environment, including the other existing economic activities, is also at the heart of the topical concept of industrial symbiosis. For instance, key actors within the watershed might benefit from the water and nutrient circularity approach, e.g. farmers in the vicinity that could re-use treated wastewater as irrigation water. We propose that the “Water and nutrient circularity as a Service (WaNCaaS)” starts with analyzing the situation and its context, and identifying options for water and nutrient circularity, in order to co-design with the food industry the most appropriate system.

As this is a highly innovative comprehensive service model that we want to develop, we would like to investigate whether and under which conditions such a service model could thrive and be sustainable. Following questions arise: when could water and the nutrients it contains be recovered from food industry wastewater? Under which conditions is it practicable technically, economically and socially?

Specifically, based on case studies with our implementation partners, we will consider the following determinant factors, among others: wastewater volume produced, its composition and seasonality, technical methods to reduce and reuse, economics of the processes (cost-benefits analysis, business case), local discharge guidelines and legislation, and other relevant stakeholders to this service model. The project scope includes socio-technical system analyses based on several archetypes differing in volumes and diversity of the wastewater produced. Eisberg AG is an industry producing packaged salad, which generates all year long a big volume of wastewater mostly from washing. Hilcona AG is an industry with a seasonal production of diverse food products, which generates different types of wastewater along the year, depending on the seasonal production. Natürli AG is an industry producing cottage cheese, which generates all year long, but weekly, a small volume of wastewater. We will address the following questions: What would be possible for them, and at what cost? And what should the system have in place so that a change happens? Results of our feasibility study could for instance include in a first step a temporal mapping of wastewater generation; proposing flexible and adaptable recovering processes that can treat different wastewater around the year; price ranges for clean water and nutrient recovery if offered as-a-service to the industry; potential pricing of treated wastewater for other stakeholders, e.g. farmers. The challenge is to design a service business model that is economically viable.

WaNCaaS aims to make the food system more circular, from small to large scale food processing industries. The innovation lies in a comprehensive service model for the food industry to close water and nutrient loops around their factory, by potentially including key actors in the vicinity and watershed for a sustainable, among others resource-efficient, and future-oriented operation.

The concept we propose for WaNCaaS will link food industries with technological innovations and key actors, while reducing the need for development of internal structures to maintain and operate new technologies, through a service model setup.

The WaNCaaS project will enable further co-design of industrial symbiosis, merged with innovative business models, to realize a circular economy approach focused on both water and nutrients.

The main actors (potential customers of WaNCaaS) involved are the implementation partners (see above). We are also interested in the beneficiaries of clean water and recovered nutrients. Interactions will consist mostly of semi-structured interviews, workshops and on-site industry visits.

In the early step of context analysis, actor network analyses will be conducted. Depending on the results, involving further local actors (e.g. farmers, other industries) might be necessary.

We build an inter- and transdisciplinary team, which covers the necessary domains of expertise to successfully carry out the WaNCaaS project. The following domains are covered: technical knowledge on water and wastewater treatment and nutrient recovery (Maximilian Grau), participatory decision-making and sustainability assessment (Alice Aubert), economical knowledge and innovative business model development (Grégoire Meylan). The practical food industry knowledge and expertise (with their various specificities) is brought by our implementation partners.

WaNCaaS has a positive impact on all aspects of sustainability, thanks to its comprehensive integration of innovations from different fields. First, it tackles environmental sustainability by reducing net water consumption, and by saving resources through the recovery of valuable nutrients. Second, it tackles social aspects of sustainability, by developing a new service model, in which various actors are brought together in “symbiosis” relationships. In addition, WaNCaaS can contribute to creating new jobs, if its feasibility is proved and a new sector thrives around water and nutrient circularity services. Finally, it can be economically relevant for the food industries, as production costs may be reduced thanks to water savings, and the potential new side-products generated by the chosen circularity option. Finally, reducing the environmental costs of their food production, the industries may benefit from a competitive sales argument on the market.

WP1: Water and Nutrient Stewardship (aube) CHF 8’190

- Identify key actors in watersheds / internet search and surveys

- Specify their needs, interests and resources / interviews

WP2: Water and nutrient characterization (grux) CHF 13’650

- Water and nutrient balance for factories of implementation partners / mass balance

- Characterize wastewater: quality, seasonality, etc.

- Retrieving partners’ available data, on-site data collection and analyses if needed

WP3: Mapping of potential technologies and matching (grux) CHF 9’282

- Database of potential technologies for water and/or nutrient recoveries

- Propose options to manage wastewater streams characterized in WP2, to meet needs identified in WP1 / Multi-Criteria Decision Analysis

WP4: Business model development (melg) CHF 8’190

- Screening business models / business model canvas

- Comparative business case analysis (business-as-usual, alternative, circular system), with input from WP 2 and 3

- Refining business model canvas based on business case analysis and interviews from WP1

Work flow: WP1 and WP2 in parallel, followed by WP3, and finally WP4.

Total: CHF 39’312

This project consists of a feasibility analysis. Next step, if proven feasible, will be to develop the service model with an external partner to a potential business product, e.g., through Innosuisse funding. With the three diverse case studies, implementation and evaluation, the WaNCaaS model will undergo a reality check for food industries. If successful, a new service model has emerged to reach water and nutrient circularity.